|

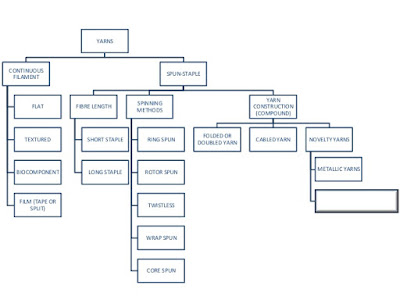

| Classification of yarns |

1. Spun yarn

Spun staple fiber yarn consist of staple fibers assembled

and bound together by various means to produce the required characteristics

such as strength, handle, appearance, etc. spun yarns are composed of staple

fibers (short length fibers) twisted or spun into a single thread-like strand.

A high twist is generally needed for the fibers to create a strong yarn.

2. Continues filament yarns

Continues filament yarn are produced by either combining the

required number of filaments together as in the silk throwing process or, more

commonly as in the case of manmade fibers, by producing the required number of

filament and thickness of filaments simultaneously in one spinning operation

Because of the unbroken nature of the fiber, a low twist is

enough to create a smooth and lustrous yarn. The typical filament yarn is,

therefore, a collection of parallel filaments lying close together and

virtually straight running the whole length of the yarn. Yarn with one filament

is referred to as monofilaments and those with more than one as multifilament.

1.Ring spun yarns

Ring spun yarns are produced on the ring and traveler system

from a wide variety of fiber types. This is most popular system of staple fiber

yarn production, being able to utilize a wide range of fiber types, fiber

fitness and fiber length. The component fibers are twisted around each other to

set up frictional forces between the fibers to impart strength to the yarn

2.Rotor spun yarn (open end yarns)

Like ring spun yarns, they consist of fibers bound together

by twist. Rotor spun yarns are generally only produced from short staple

fibers. There are a number of differences in quality between ring and rotor

yarns; in general, rotor yarns are more regular but weaker than comparable ring

spun yarns.

3.Twist less yarn

Twist less yarn are yarns produced from staple fibers where

the consolidation of the fibers is by means of some form of adhesive

4.Wrap spun yarns

Yarns consisting of parallel bundle of staple bound into a

compact structure by another yarn, usually continuous filament. Can be produced

using both long and short staple fibers.

5.Core spun yarns

Core yarns are characterized by having a central core

wrapped with staple fibers. These are produced in a sigle operation by feeding

a yarn through the delivery rollers of a spinning flame, simultaneously with

staple fibers

Core yarns can be produced in three different form such as :

-

Cotton with filament core;

-

Hair fibers with cotton core;

-

Various fibers with electrometric core;

6. Self twist yarns

Self- twist yarns are two ply yarns produced in a single

operation. During manufacture, each component is twisted in alternating directions

in short segments. The two components are subsequently put together in such a

way they twist together (self – twist) to form the final yarn. Self-twist yarns

are predominantly produced from long staple fibers

7. Friction spun yarn

Produced on spinning system which use two rotating rollers

to collect and twist individual fibers into a stable yarn structure.

8. Fascinated yarns

Fascinated yarns are yarns produced from staple fibers where

the consolidation of the fibers is by means of some form of adhesive.