Fabric classification

Fabrics can be divided into three

basics types: woven, knitted, and non woven

Woven fabrics

Woven fabrics are produced by

interlacing of two set of yarns which are perpendicular each other in a loom. The

length-wise yarn is called warp or ends. The width-wise yarn called weft,

fillings, or picks. Edges of the fabric width are called selvages. The purpose

of having selvages is to prevent tear of the cloth during finishing processes. Yarn

density in textile is a measure of fabric quality. Therefore, the higher the

number of yarns per inch results in a better quality fabric.

Weaving preparation

Before weaving process, there is

a preparation process for warp and weft yarn. The flow process of waving is a below:

Warp yarns are prepared through the process of warping, sizing and typing in, and then warp boom is put the back of the loom, or rewinding for shuttle less loom, and then put them at the side of the loom accordingly

Next step is weaving process, either using the conventional loom with shuttle which carries picks interlace with warp yarns or shuttle less loom (gripper, or water jet loom). The result of the weaving is called grey fabrics (unfinished fabrics)

In the old days, weaving is done

by using what so called “hand loom”

After revolution of industry, weaving machine was invented called as conventional loom which using shuttle to carry the weft yarn interlace with warp yarn. Nowadays, much further advance technology used to innovate the weaving machine. Then, consecutively found new machinery such as, automatic shuttle change loom, automatic cop change loom, projectile (gripper) loom, rapier loom, water jet loom and air jet loom.

The goal of technology innovation in wearing is mainly to increase productivity, increase efficiency, reduce the wastage of yarn during weaving, and decrease manpower to handle the machine which means one operator may be can handle more than 20 looms.

Weaving mechanism

Weaving is carried out on a

machine traditionally known as a loom, but the term weaving machine has been

used in more recent y years to indicate the high standard of precision

engineering that is used in its manufacture today.

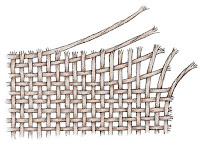

In pic beside, shows a cross

section through a typical loom, with the warp ends being contained on the

weaver’s beam at the back of the loom. From this point, each end successively

passes through the eye of a heald (with group of healds being mounted within

heald frames) and through the gaps (known as dents ) between the wires of the

reed, which is basically a closed comb. In front of the reed, the warp and weft

combine at the fell to form fabric, which is then drawn forward to be stored on

the cloth roller.

In pic beside, shows a cross

section through a typical loom, with the warp ends being contained on the

weaver’s beam at the back of the loom. From this point, each end successively

passes through the eye of a heald (with group of healds being mounted within

heald frames) and through the gaps (known as dents ) between the wires of the

reed, which is basically a closed comb. In front of the reed, the warp and weft

combine at the fell to form fabric, which is then drawn forward to be stored on

the cloth roller.

Basic weave

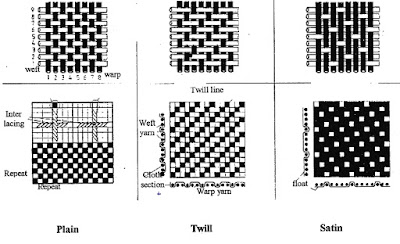

There are three basic weaves:

plain, twill, and satin. Other weaves are descendant (elaboration ) of the

three weaves

Plain

Plain weave: the simplest form of

weaving a pick (filling yarn) passes over the first end (warp yarn), under the

second and on continuously, over one end and under the next. The next pick

alternates, passing under the first end, over the second and on continuously

under and over each end. Each filling row alternates, thus extending the

fabric. Also called a one up one down weaves

Twill

Twill is a general term for woven

fabric made with a twill weave, a basic weave characterised by diagonal lines

on the face of the fabric. Twill can be 2/1 or 3/1

Satin

Satin is a smooth strong,

lustrous satin weaves fabric made with silk or manufactured filament yarns. In

the warp face satin, the most common, the filling yarns cross over one and under

several warp yarns, thus mainly the wrap yarns are visible on the face. In a

filling face satin, the filling yarns cross under one and over several warp

yarns thus the mainly the filling yarns are visible on the face. Some satins

have a filament yarn face and spun yarn back