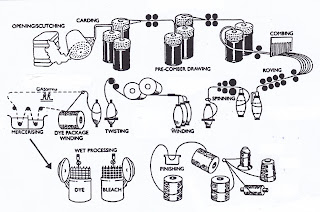

the process of making yarn

|

| Yarn process |

By definition, yarn is an assembly of substantial length and

relatively small cross section of fibers and/or filaments with or without twist

(textile institute)

From fiber to yarn, there is a series of process such as

blowing, carding, drawing, roving (flyer), spinning, and winding

First, in fact, blowing process consist of series of

machineries that ended with scutching machine. The function of blowing process

is to open the fibers from the balls, blending, cleaning, and lap forming.

Second machine is carding that has function cleaning,

sorting out very short fibers from main fibers, and sliver forming. For yarn

count below 40, third machine is drawing. Its function drafting fibers into

more parallel, improving the evenness of weight per certain length, and silver

forming.

Third, for fine yarn count, above 40, there will be combing

process, which is done in combing machine. Combing function is to separate

intended length of fibers to continue to next process (sorted out the short

one), drafting, parallezing, improving the evenness, and silver forming

Fourth, roving or flyer machine, which function drafting,

slight twisting, and winding in roving form.

Fifth, ring spinning machine, which function drafting,

twisting and winding yarn in the form of bobbin. The last machine is winding,

which function re- winding the yarns into cones or cheese winding form. In the

case of opened end yarns, after process of drawing goes directly to open end

spinning machine, which the same function with ring spinning, only different

method.

For sewing thread, there will be additional process such as

doubling, twisting, mercerizing, bleaching, dyeing, finishing, and finally re

winding according to winding format intended.